What is Chemical Reactor?Chemical reactors are vessels designed to contain chemical reactions. Reaction Vessels are also used for other processes such as solids dissolution, product mixing, distillation, crystallization, liquid/liquid extraction and polymerization. Reactors are also identified based on process for which it will be used. (Such as blender or crystallizer). We are a chemical reactor manufacturer for Chemical, Pharm and other industries. Type of Chemical Reactors we fabricate-As per your process demand we fabricate jacketed vessel, limpet coil reactor, dimple type reactor, high pressure reactor or autoclave. Benefits of our product

• Complete range of chemical reactors as per your specifications |

|

|

A jacketed vessel is a container that is designed for controlling the temperature of its contents, by using a cooling or heating "jacket" around the vessel through which a cooling or heating fluid is circulated. A jacket is a cavity external to the vessel that permits the uniform exchange of heat between the fluid circulating in it and the walls of the vessel Gurukrupa Engineering is a proven jacketed vessel manufacturer. Jacketed vessel can also be offered in Dimple design. Benefits of our product

• Available in the range.

|

|

|

Limpet coil reactor vessels are used to control the temperature of the reactants with the help of heating or cooling media circulated through coils surrounding the main vessel. Ideally suitable for medium heat transfer requirement and heating application where heating media temperature is above 150 Centigrade (302 Fahrenheit). Coils are half piped welded on the outer side of the main vessel. Benefits of our product

• Limpet coil reactor can be used for heating or cooling of the reactants

|

|

|

Distillation is the process of separating liquid mixture into its component parts. It also known as fractional distillation. Distillation column is the heart of the distillation system. Benefits of our product

• Distillation column can be manufactured to accommodate packing or tray.

|

|

|

Distillation is a process of separating the component substances from a liquid mixture by selective evaporation and condensation. Distillation may result in essentially complete separation (nearly pure components), or it may be a partial separation that increases the concentration of selected components of the mixture. In either case the process exploits differences in the volatility of mixture's components Benefits of distillation equipment manufactured by Gurukrupa Engineering

• We manufacture complete distillation system or individual equipment for distillation process

|

|

|

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc. Construction and Manufacturing of Shell and Tube Exchanger- Main components of Shell and Tube type heat exchanger are- Shell, Tube, Tube sheet, Baffles, Tie roads spacers and Channel. ShellThe cylindrical shell can be fabricated from rolled plate or from pipes. TubesTubing may be seamless or welded. Seamless tubing is produced in an extrusion process; welded tubing is produced by rolling a strip into a cylinder and welding the seam. Welded tubing is usually more economical. Tube sheetTubesheets are plates or forgings drilled to provide holes through which tubes are inserted. Tubes are appropriately secured to the tubesheet so that the fluid on the shell side is prevented from mixing with the fluid on the tube side. Holes are drilled in the tubesheet normally in either of two patterns, triangular or square. BafflesBaffles are provided to support the tubes, to maintain the space between the tubes and it also channelized the fluid flow as per design through the shell side of heat exchanger. Tie Rods and SpacersTie rods and spacers will hold the baffle assembly together; and will also maintain the spacing between the baffles. One end of the tie rods are secured to the tube sheet and other ends are secure in the last baffle. Channels (Heads)Channels or heads are provided for shell-and-tube heat exchangers to contain the tube side fluid and to provide the desired flow path. Application of Shell and Tube ExchangerShell and tube heat exchangers are used as condensers, reboilers, process heaters, coolers and falling film evaporator. Benefits of Gurukrupa Engineering Shell and Tube Heat Exchangers

• Also offered with fin tube or corrugated tubes. As these design offered higher heat transfer area.

|

|

|

Chemical tanks are storage containers for chemicals. They come in a variety of sizes and shapes, and are used for static storage, processing, mixing, and transport of both raw materials and finished chemical products. We offer horizontal as well vertical chemical tanks. Benefits of Gurukrupa Engineering Chemical storage tanks• Size available as per requirement

|

|

|

The OCTAGONAL BLENDER is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. The Octagonal Blender gives best result for granules due to very slow speed and octagon shape of container. In Octagonal Blender the granules comes from all sides due to the octagonal shape of the product container, hence requirement of RPM is less. Suitable mainly for Crystalline & Granular type material. This type of material gets sufficient continuous movement due to their shape if container have only slow movement and will results in good quality of blending / lubrication of granules. It is very useful for pharmaceutical industries wherein gentle blending of dry granules of powder is to be done. It is a slow speed blender and has removable type baffles mounted on a rectangular shell. The important feature of the machine is easy to wash in place. It can also be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Special Features of Octagonal Blender• Octagonal Blender is Suitable for dry mixing of products in granule form.

|

|

|

The V-Blender is a popular tumble blender commonly used in the pharmaceutical and food industries. This article explains the design, construction, and operation of the standard V-Blender and the V-Blender with intensifier bar. The advantages and the disadvantages of the V-Blender are highlighted. Advantages of Using V-Blender• Particle size reduction and attrition are minimized due to the absence of any moving blades. Hence it can be used for fragile materials

|

|

|

The Mass Mixer Machine is basically mixing a assembly wherein the mixing stirrer is in horizontal position in the container & have a single speed, simple rotation. The stirrer rotates around itself at a very slow speed inside the bowl and thereby achieving intimate mixing of dry or wet materials of Tablet Granulation, Powder, Chemicals, food& Confectionaries Materials.

Special Features• Range of Mass Mixers models to suit working volume 50,100 & 200 Kgs. At bulk density of 0.50 gms/cc.

|

|

|

The dryers are made of trays held in a cabinet which is connected to a source of air heated by gas, diesel or bio-mass such as rice husk. The air temperature is usually controlled by a thermostat which is normally set between 50 and 70OC. The air enters the bottom of the chamber below the trays and then rises, through the trays of food being dried, and exits from an opening in the top of the chamber. In the Practical Action systems the trays are designed to force the air to follow a longer zigzag route which increases the air/food contact time and thus improve its efficiency. This system also reduces back pressure which means that cheaper, smaller fans can be used. |

|

|

These Conventional Coating Pan are widely used in various pharmaceutical industries for film and sugar coating. Our Conventional Coating Pans are the perfect manual tablet coating system. The elliptical shaped standard coaters attached with these Conventional Coating Pans are mounted on 30 degree. The pans offered by us are available with the pulley that has variable speed. In these pans, there are inbuilt systems of supply for hot air and can be availed with the specifications of 48’ size. The system for hot air in these pans has high capacity. There is also a delivery pipe, which has temperature ranging between 30°C to 75°C. We are looking queries from Hyderabad, Andhra Pradesh region only. Special Features• Anti vibrating unit provided for proper levelling, hence no requirement of foundation

|

|

|

Multi Mill is widely used for wet and dry granulation pulverization etc. in Pharmaceuticals, Chemicals Cosmetics, Ceramics, Colors, Dyestuff, Food products etc. it also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastics and Resins Industries.

Special Features• cGMP point of view machine is provided with SS cladding on base, pillar, machine chamber, SS cover on motor. No exposed painted surface on top of the machine.

|

|

|

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc.

|

|

|

The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Features of Double Cone Blenders:

• The conical shape at both ends of Double Cone Blender enables uniform mixing and easy discharge.

|

|

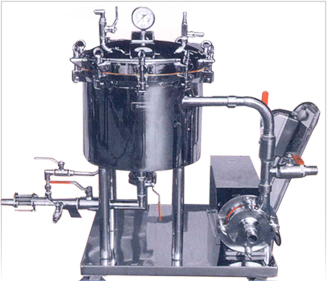

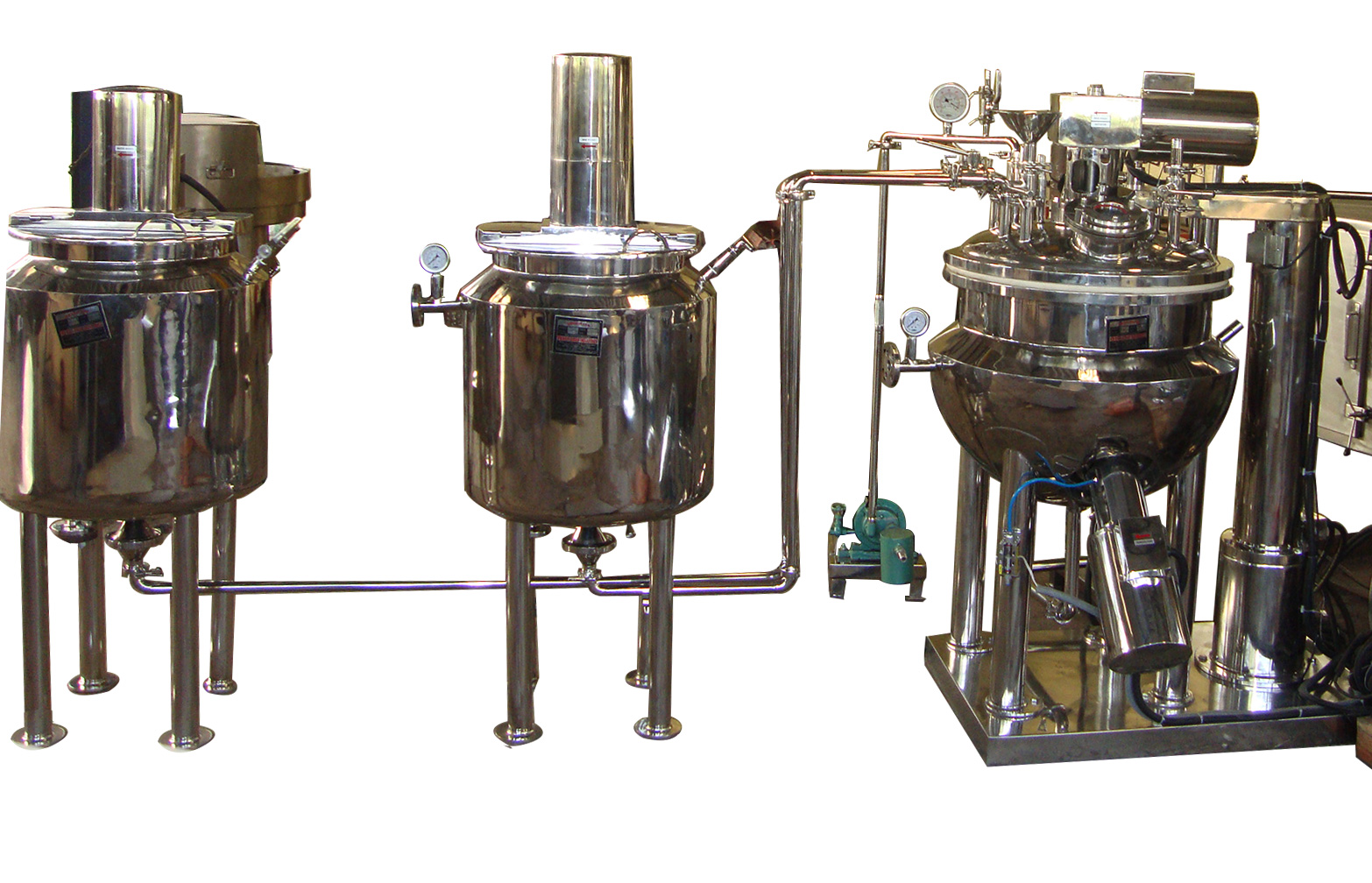

DescriptionCatering to the requirements of the pharmaceutical industry, we offer Pharmaceutical syrup manufacturing vessels in India Available in various batch capacities from 500 to 10,000 liters. It is extensively used for the preparation of pharmaceutical liquid oral preparation. Sturdy in construction the plant is provided with main syrup manufacturing vessel, sugar preparation vessel and storage vessel. For sugar filtration, it is provided with sparkler / housing filter and sparkler filters for final filtration.

Features• Plant is provided with interconnecting piping with pumps and valves

Primary Components• Sugar / primary syrup manufacturing vessel.

Salient Features• The plant is designed as per the CGMP and FDA guidelines.

Optional Features• Vacuum loading system for the primary (sugar) preparation vessel.

|

|

Horizontal Sparkler Filter Reverse Flow (Zero Hold Up)Principle of OperationLiquid is pumped through the central channel of the cartridge from the bottom of the body. Suspended particles are retained on the filter media resting on the filter plate. Clean filtrate emerges out from the peripheral holes of the plate, into the tank and comes out from the bottom outlet. Filter tank wall does not come in contact with the un-filtered liquid, hence remains clean. Feature of Reverse Flow Model• Zero Hold Up of filtrate with out scavenging operation.

|

|

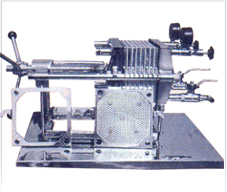

Horizontal Plate Sparkler FiltersThe horizontal sparkler type filter is the most versatile filtration system for solid – liquid separation. It can also be used apart from filtration, with the help of filter aids for giving a sparkling effect to the liquids filtered. The filters are most suited for the filtration of products for the pharmaceutical, chemical, distillery, beverage, ink, oil and other allied industries. It is available in different output capacities with a variety of pumps to suit individual requirements. Horizontal Plate Sparkler Filters:- horizontal sparkler type filter is the most versatile filtration system for solid – liquid separation and available in different output capacities. |

|

|

ConstructionThe filters are made out of Stainless steel in S.S. 304, 316 & 316 L qualities. The cartridge assembly consists of a number of disc type filter plates with perforated support screen, filter media and interlocking cups placed one on top of the other and supported at the bottom by a cartridge plate. The entire assembly is held together with the help of side tie rods which are of ‘T’ type construction for longer life. The filter together with the pump and interconnecting piping is mounted on a sturdy base cladded with S.S. sheets and provided with castors for movability. The filter can also be supplied without pump, where external positive pressure is available. |

OperationThe liquid to be filtered is passed into the vessel by means of the pump or other external means. The liquid then passes through the top of the filter plates from the holes provided at the side of the plate and onto the filter media. The liquid flows simultaneously and individually through all the member plates. Hence the output of the filter depends on the diameter and the number of plates. The filter media then retains the impurities in the liquid and the filtered liquid passes through the central channel to the outlet at the bottom. The filters are optionally available with steam jacket for filtration of difficult liquids that solidifies at lower temperatures. These types of filters are generally used for obtaining clear filtrate, but it can also be used to obtain the cake that is retained on the filter media, between the plates. |

|

Salient Features |

||

18 Dia Filter with Lobe Pump |

14" Dia Filter with Centrifugal Pump |

18" Dia Filter with Steam Jacket |

|

•

The complete filter plate is manufactured by cold process.

|

||

Scavenging OperationThe unfiltered liquid remaining inside the shell at the end of filtration can be filtered by scavenging operation, opening the single plate valve and applying pressure from the vent using compressed air or nitrogen / inert gas, so that even the last drop of unfiltered liquid passes through the bottom plate. It is available in 14” & 18” Dia models as a standard and can be provided in 33” Dia model on request. |

SIZE |

TYPE OF PUMP |

MOTOR |

TYPE OF SEAL |

Ht. OF PLATES |

FILTERING AREA |

CAKE CAPACITY |

FLOW RATE Ltrs / Hr. |

8” Dia X 8 Plates |

Gear |

1 HP-1440 |

Oil Seal |

25 mm |

0.2 m Sq. |

Ltrs. |

450 - 500 |

8” Dia X 8 Plates |

Gear |

1 HP-1440 |

Oil Seal |

25 mm |

m Sq. |

Ltrs. |

600 - 700 |

8” Dia X 8 Plates |

Centrifugal |

1HP-2800 |

Mechanical* |

25 mm |

0.2 M Sq. |

Ltrs. |

450 - 500 |

8” Dia X 8 Plates |

Centrifugal |

1HP-2800 |

Mechanical* |

25 mm |

0.25 M Sq. |

5.6 Ltrs. |

600 - 700 |

14” Dia X 8 Plates |

Centrifugal |

2 Hp-2800 |

Mechanical* |

38 mm |

0.65 M Sq. |

22 Ltrs. |

1300 - 1500 |

14” Dia. X 10 Plates |

Centrifugal |

2 Hp-2800 |

Mechanical* |

38 mm |

0.81 M Sq |

27 Ltrs. |

1500 - 1700 |

18” Dia. X 8 Plates |

Centrifugal |

3 Hp-2800 |

Mechanical* |

50 mm |

1.15 M Sq. |

51 Ltrs. |

2500 - 3000 |

18” Dia. X 12 Plates |

Centrifugal |

3 Hp-2800 |

Mechanical* |

50 mm |

1.72 M Sq. |

Ltrs. |

4000 - 4500 |

18” Dia. X 15 Plates |

Centrifugal |

3 Hp-2800 |

Mechanical* |

25 mm |

2.15 M Sq. |

40 Ltrs. |

5000 - 5500 |

18” Dia. X 23 Plates |

Centrifugal |

3 Hp-2800 |

Mechanical* |

25 mm |

3.3 M Sq. |

61.5 Ltrs. |

8000-8500 |

33” Dia. X 7 Plates |

Centrifugal |

5 Hp-2800 |

Mechanical* |

38mm |

4.01 M Sq. |

105 Ltrs. |

9000-9500 |

33” Dia. X 10 Plates |

Centrifugal |

5 Hp-2800 |

Mechanical* |

38mm |

5.51 M Sq. |

150 Ltrs. |

12500-13000 |

33” Dia. X 14 Plates |

Centrifugal |

5 Hp-2800 |

Mechanical* |

38mm |

7.52 M Sq. |

210 Ltrs |

17500-18000 |

|

* - Mechanical Sal is provided with Tungsten carbide VS Tungsten Carbide face combinations. |

|||||||

Plate and Frame Filters PressThe plate and frame type filter press is highly suitable for the filtration of viscous products and for large volume filtration. The filter press consists of a number of rectangular plates and frames arranged vertically one after the other and supported by two side tie bars. The filter media is sand witched between the plates and the frames. It is available in various sizes and number of plates. The filter press is provided with a mechanical closing system and two end plates. |

Salient Features | ||

|

|

• Available in S.S. 304/ 316/ 316 L Quality.

|

Transfer Pumpswe manufactures a various types of transfer pumps like centrifugal and lobe pumps. The centrifugal pump is suitable for transferring free flowing non viscous liquids, while the lobe pump is highly suitable for transferring highly viscous liquids like ointments, creams, glycerin, etc. the pumps are available in various output capacities and heads depending on requirement. The pumps are fitted with mechanical seal to give leak proof and trouble free operation. |

|

DescriptionWe are amongst the reputed manufacturers and exporters of Ointment Manufacturers Plant in India. Designed to perfection, the plant is extensively used for manufacturing pharmaceutical ointments, cream, sterile preparations, cosmetic, suspensions and gels. For optimum performance, the plant is provided with water phase vessels, main manufacturing vessel and pre-mixing wax. For emulsifying, the main vessel is provided with bottom high-speed homogenizer and slow speed anchor agitator for mixing.

Specification

Primary Components

•A jacketed water heating vessel with direct coupled stirrer.

Salient Features

•The plant is designed as per the CGMP and FDA guidelines.

Optional Features

•Load cells with control unit for the main manufacturing vessel.

|

|

DescriptionThe function of filtration equipment is to filter slurry so as to separate the solid more or less completely from the liquid.

|

|

Complete range of chemical reactor for Chemical, Pharma and other industries. Read More...

A jacketed vessel is a container that is designed for... Read More...

Limpet coil reactor vessels are used to control the temperature... Read More...

A shell & tube heat exchanger is a class of heat exchanger designs. Read More...

The Octogonal blenders is an efficient and versatile blending machine for mixing and ...Read More...

The V-Blender is a popular tumble blender commonly used in the pharmaceutical and food ...Read More...

The Double Cone Blender is an efficient and versatile machine...Read More...

The Mass Mixer Machine is basically mixing a assembly wherein...Read More...

The Ribbon blenders is an efficient and versatile blending machine...Read More...

The dryers are made of trays held in a cabinet which is connected to a source of air heated by gas, diesel...Read More...

These Conventional Coating Pan are widely used in various pharmaceutical industries...Read More...

Multi Mill is widely used for wet and dry granulation pulverization etc...Read More...

It is extensively used for the preparation of pharmaceutical liquid oral preparation ...Read More...

Different Type of Sparkler filters which is used for ...Read More...

In Nutsche filter force required for separation of filtrate is through ...Read More...

Designed to perfection, the plant is extensively used for manufacturing pharmaceutical ointments ...Read More...